Wood cylinders are integral to industries ranging from furniture manufacturing to large-scale construction. Their versatility, strength, and accuracy make them indispensable for structural and decorative applications. Sourcing high-quality wood cylinders from reliable wood product manufacturers is essential to maintain industry performance and efficiency.

This post delves into the industries that depend on wood cylinders, their diverse applications, the challenges of sourcing top-tier components, and the advantages of working with trusted wood manufacturing companies for superior solutions.

The Role of Quality Wood Cylinders in Industrial Applications

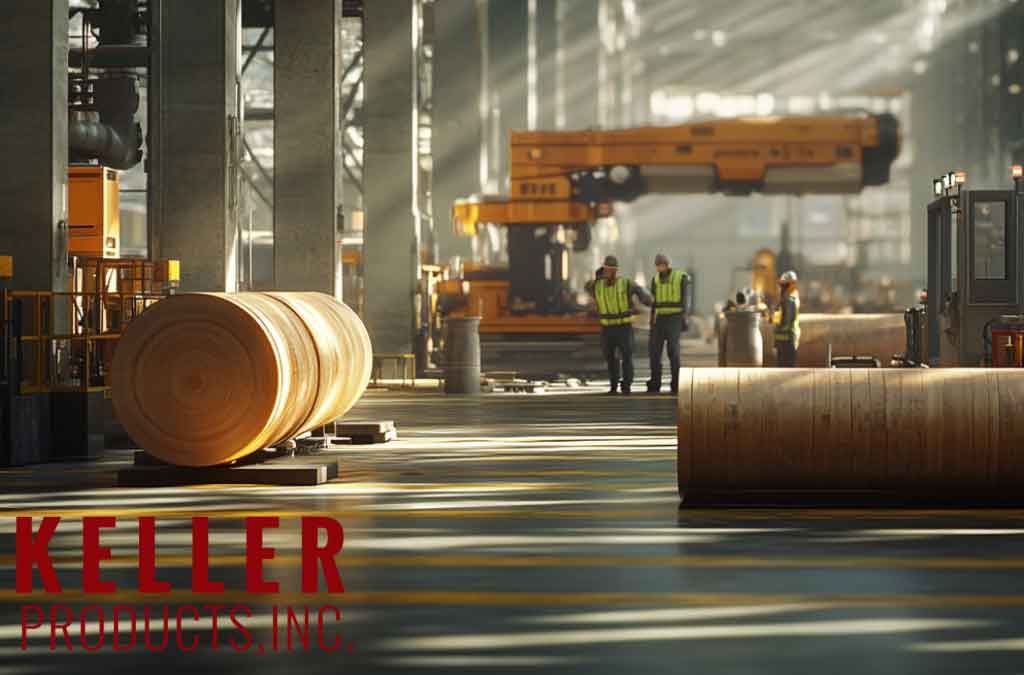

Wood cylinders serve as indispensable components in industrial settings, where strength, durability, and mastery are essential. Whether supporting large-scale machinery or ensuring structural integrity, these cylinders are crafted to meet the exacting demands of high-performance environments. Their adaptability and reliability make them a cornerstone in industries that require consistent quality and robust functionality.

This sets the stage for a deeper exploration of how premium-grade materials and engineering elevate the performance of wood cylinders in critical applications.

The Value of Premium-Grade Resources

The reliability of wood cylinders begins with the materials used to create them. High-quality hardwoods like oak and maple offer exceptional strength and durability, while softwoods like pine provide flexibility and cost-efficiency for decorative applications. Superior material selection enhances the overall functionality and safety of these critical components.

- Durability in Critical Applications: High-grade wood cylinders are built to withstand heavy loads, wear, and environmental stress. Their robust construction makes them ideal for use in demanding industries such as construction and furniture manufacturing.

- Safety in Operations: Industrial projects demand materials that reduce the risk of failure. Premium manufactured wood products ensure safer project execution, minimizing accidents and system malfunctions.

- Longevity: Quality materials guarantee that wood furniture parts, scaffolding, or decorative elements maintain their integrity over time. This durability translates to cost savings and improved project efficiency.

By focusing on premium materials, wood manufacturing companies ensure their products deliver exceptional performance in even the most demanding conditions.

Consistency and Precision in Design

Dimensional accuracy and consistent quality are essential for wood cylinders to function effectively in industrial applications. Expert craftsmanship ensures these components integrate seamlessly into existing systems, enhancing both functionality and aesthetics.

- Seamless Integration: Cylinder wood with precise dimensions aligns effortlessly with other components, ensuring stability and uniformity in industrial frameworks.

- Uniformity: Consistent sizing and smooth finishes contribute to projects’ aesthetic and structural appeal, especially in applications like wood furniture parts and architectural installations.

- Error Reduction: Advanced manufacturing techniques minimize the risk of mismatched parts or assembly errors, eliminating costly rework and preventing project delays.

By adhering to stringent quality standards, wood product manufacturers create wooden cylinders that meet their client’s specifications, delivering unmatched reliability and performance across various applications.

Key Industries That Depend on Wood Cylinders

Industries worldwide rely on wood cylinders for their unmatched versatility and dependability. These components form the backbone of numerous applications, from manufacturing and construction to creative design.

Manufacturing Sector

The manufacturing sector relies on wood cylinders for their precision, adaptability, and ability to enhance both functionality and aesthetic value. These components play a vital role in streamlining production processes while ensuring the quality of finished products.

Furniture Production

Wood cylinders are indispensable in furniture manufacturing, contributing to both structural integrity and design aesthetics.

- Applications: Commonly used in table legs, chair frames, and decorative bases, they combine style and functionality.

- Production Consistency: Uniformly sized and finished wood furniture parts streamline production lines, improving efficiency and reducing waste.

- Structural Support: Expertly crafted components ensure the furniture can withstand everyday use without compromising elegance.

This combination of reliability and adaptability makes wooden cylinders a cornerstone in modern furniture design, supporting manufacturers in creating products that stand out in competitive markets.

Textile Manufacturing

In textile production, wood cylinders are essential for ensuring smooth machinery operation and protecting delicate materials.

- Essential Machinery Components: Used in spinning and weaving equipment, these cylinders facilitate seamless material handling and prevent disruptions.

- Polished Surfaces: Smooth finishes minimize fabric snags or damage, contributing to higher-quality textiles.

- Operational Dependability: Durable construction reduces equipment wear and downtime, supporting efficient and consistent production runs.

By addressing the specific needs of textile manufacturing, wood cylinders help optimize processes while maintaining high standards of product quality.

Printing and Packaging

Wood cylinders play a pivotal role in the printing and packaging industries, where precision and reliability are critical.

- Core Applications: Integral to printing rollers and packaging machinery, they ensure smooth and efficient operations.

- Dimensional Accuracy: Components crafted to exacting standards reduce defects, improving output quality.

- Cost Efficiency: Long-lasting cylinders minimize maintenance needs, helping businesses control costs while maintaining productivity.

These expertly engineered wooden cylinders are an asset in industries where precision and reliability directly impact operational success.

Construction Industry

The construction industry depends on wood cylinders for their strength and stability in large-scale projects. These components are engineered to withstand heavy loads while offering flexibility in various applications.

Scaffolding and Structural Frameworks

Wood cylinders are widely used in scaffolding and structural frameworks due to their excellent weight-bearing properties.

- Applications: Used as supports in scaffolding and concrete formwork, they provide essential stability.

- Standards: Their durability ensures compliance with safety regulations, making them suitable for high-demand projects.

- Efficiency: Lightweight hollow wood tubes reduce material weight without compromising structural integrity, improving handling and installation efficiency.

These features make wooden cylinders a trusted choice for ensuring safety and performance in construction.

Roofing and Siding Applications

Wood cylinders play a crucial role in shaping materials while maintaining consistency in roofing and siding.

- Role: They are used to roll and shape roofing and siding materials, ensuring uniformity across installations.

- Features: Smooth, high-quality finishes enhance the aesthetic appeal of finished products.

- Reliability: Expertly crafted hollow cylinder components meet the stringent standards of modern construction, delivering dependable and consistent performance.

Their versatility and durability make wood manufacturing company solutions indispensable for roofing and siding professionals.

Creative Design and Artistic Applications

The creative design and artistic industries embrace wooden cylinders’ adaptability to bring unique visions to life. These components support both functional and aesthetic elements in diverse projects.

Artistic Installations

Hollow wood tubes are popular for sculptors and designers seeking innovative materials for large-scale or intricate creations.

- Versatility: Customizable sizes and finishes accommodate a wide range of artistic requirements, from structural elements to decorative features.

- Durability: Strong materials ensure longevity, even in outdoor installations exposed to environmental factors.

- Aesthetic Appeal: Polished surfaces provide a sleek, professional look, enhancing the visual impact of the artwork.

Their unique qualities make wood cylinders a preferred material for pushing creative boundaries.

Interior and Lighting Design

In interior and lighting design, wooden cylinders blend functionality with aesthetic value, creating harmonious and innovative solutions.

- Applications: Common uses include custom lighting fixtures, decorative columns, and accent pieces for commercial and residential spaces.

- Value: These components integrate seamlessly into diverse design themes, offering timeless appeal and versatility.

- Flexibility: Custom dimensions and finishes provide creative freedom, enabling designers to craft distinctive and functional elements.

Whether supporting elegant lighting designs or adding a decorative touch, wood manufacturing company products continue to inspire innovative interior solutions.

Where to Source High-Quality Wood Cylinders

Finding a reliable source for wood cylinders is crucial to ensure consistent quality, supply, and cost-efficiency. Partnering with experienced wood manufacturing companies helps businesses access premium materials tailored to their specific needs.

Identifying Reliable Suppliers

Choosing the right supplier is key to obtaining manufactured wood products that meet rigorous standards. Reputable wood manufacturer provide dependable solutions designed to align with diverse project needs while upholding quality and compliance.

What to Look For in a Supplier

Identifying a trustworthy partner involves assessing their expertise, credentials, and performance. Key considerations include:

- Experience: The supplier’s proven success in wood product manufacturing across multiple industries demonstrates its ability to handle varied applications and challenges.

- Certifications: Adherence to industry standards, such as ISO certifications, ensures compliance and product reliability.

- Reputation: Positive feedback from past clients and a consistent track record reflect the supplier’s commitment to delivering exceptional results.

By focusing on these factors, businesses can confidently choose wood product manufacturers capable of meeting their specific demands.

Verifying Product Quality

Assessing product quality is vital to ensure that wooden cylinders meet your projects’ durability and precision requirements. Effective evaluation involves:

- Durability: Inspect the material’s strength and ability to withstand environmental stresses or operational wear.

- Precision: Check dimensions and finishes for uniformity, ensuring seamless integration into designs and systems.

- Feedback: Review case studies, testimonials, and real-world applications of the supplier’s products to verify performance and reliability.

These steps provide confidence that the wood cylinder hollow components sourced will deliver long-term value and functionality.

Building Long-Term Supplier Relationships

Partnering with a trusted wood manufacturing company is more than a business transaction—it’s the foundation for mutual growth, consistent quality, and innovative collaboration. These relationships are vital for ensuring seamless operations and fostering industry leadership.

Advantages of Strong Partnerships

Working with dependable wood product manufacturers provides businesses with a competitive edge:

- Reliability: A consistent supply of premium wood cylinders ensures uninterrupted project timelines and dependable results.

- Expert Guidance: Experienced suppliers offer tailored advice and innovative solutions during critical stages, streamlining processes and minimizing challenges.

- Value-Added Collaboration: Long-term partnerships create opportunities for developing customized products that meet unique project specifications.

These benefits enhance operational efficiency, build trust, and drive lasting success for businesses in competitive markets.

Negotiating Beneficial Agreements

Effective supplier relationships are built on transparent and mutually advantageous agreements that optimize sourcing and operational strategies.

- Cost Optimization: Bulk purchasing agreements reduce per-unit costs, creating significant savings for large-scale projects.

- Adaptive Flexibility: Contracts with adjustable terms accommodate evolving market demands, material specifications, or unexpected challenges.

- Open Communication: Clear and frequent dialogue ensures both parties remain aligned, enabling smoother collaboration and addressing concerns proactively.

By fostering open communication and prioritizing shared goals, businesses can build supplier relationships that support growth, innovation, and consistent quality over the long term.

Cost-Efficiency in Sourcing

Balancing quality assurance with cost-effectiveness is critical to achieving successful sourcing strategies. Focusing on economies of scale and rigorous quality control ensures that businesses receive the best value for their investments.

Bulk Ordering Advantages

Purchasing wooden cylinders in bulk from a reliable wood manufacturing company provides numerous benefits:

- Lower Costs: Economies of scale reduce the per-unit price, offering significant savings for large projects.

- Steady Supply: Maintaining sufficient inventory levels prevents delays caused by material shortages, ensuring uninterrupted project progress.

These advantages make bulk sourcing a practical and efficient solution for high-volume operations.

Quality Control in Procurement

Implementing thorough quality control measures ensures that sourced materials meet expectations:

- Delivery Inspections: Verify that shipments match specifications in terms of dimensions, finishes, and material integrity.

- Testing Protocols: Establish benchmarks to evaluate the strength, durability, and accuracy of cylinder wood, ensuring adherence to consistent and reliable standards.

By prioritizing quality at every stage, businesses safeguard their investments and build confidence in their supply chain.

Partner with Trusted Wood Manufacturers

Choosing a reliable wood manufacturing company ensures consistent access to superior-grade resources and tailored solutions. Experienced wood manufacturers bring expertise and meticulous craftsmanship to every project, ensuring businesses achieve their goals with efficiency and reliability. Their ability to handle complex industrial demands makes them an invaluable partner for industries that rely on premium manufactured wood products.

Assurance of Quality and Precision

Trusted wood products manufacturers focus on delivering products that meet exacting standards for quality and accuracy.

- Standards: High-quality wood furniture parts, wooden cylinders, and other components ensure consistent performance across all applications.

- Customization: Reputable suppliers offer tailored solutions to address unique industry requirements, from structural elements to aesthetic finishes.

- Support: Dedicated teams guide throughout the procurement process, ensuring smooth operations and reliable outcomes.

These qualities make partnering with a dependable wood manufacturer an investment in success.

Sustainable and Responsible Sourcing

Eco-friendly practices are a hallmark of reputable wood manufacturing companies, combining environmental responsibility with superior craftsmanship.

- Renewable Materials: Sourced responsibly from sustainable forestry practices, reducing environmental impact.

- Sustainability: Manufacturing processes align with industry standards for eco-consciousness while delivering durable, high-performance materials.

- Efficiency: Advanced technology minimizes waste, ensuring optimal use of resources without compromising quality.

By choosing a sustainable wood manufacturing company, businesses contribute to environmental stewardship while receiving top-tier materials. With a focus on quality and sustainability, these partnerships drive operational success and long-term growth. Businesses that prioritize high-quality materials position themselves for greater efficiency and innovation.

Enhance your operations with expertly crafted wood cylinders from Keller Wood Products. As a leader in wood product manufacturing, we offer premium solutions tailored to your industry’s needs. Contact Keller Wood Products today to learn how our commitment to quality, precision, and sustainability can help your business succeed in every project. Let’s create something exceptional together.