The debate between natural and manufactured wood products continues to shape industries like furniture, construction, and design. Each wood type offers distinct benefits, influencing project outcomes based on material performance, availability, and cost.

Choosing the correct wood is critical to achieving efficiency, sustainability, and long-term value in large-scale manufacturing. This post explores the differences between these materials, helping businesses make informed decisions to meet their project needs.

What Is Manufactured Wood?

Manufactured wood, also known as engineered wood, provides industries with consistency, scalability, and cost efficiency. This material transforms raw wood into composite products tailored to meet specific performance standards, making it essential for various industrial applications.

The Basics of Manufactured Woods

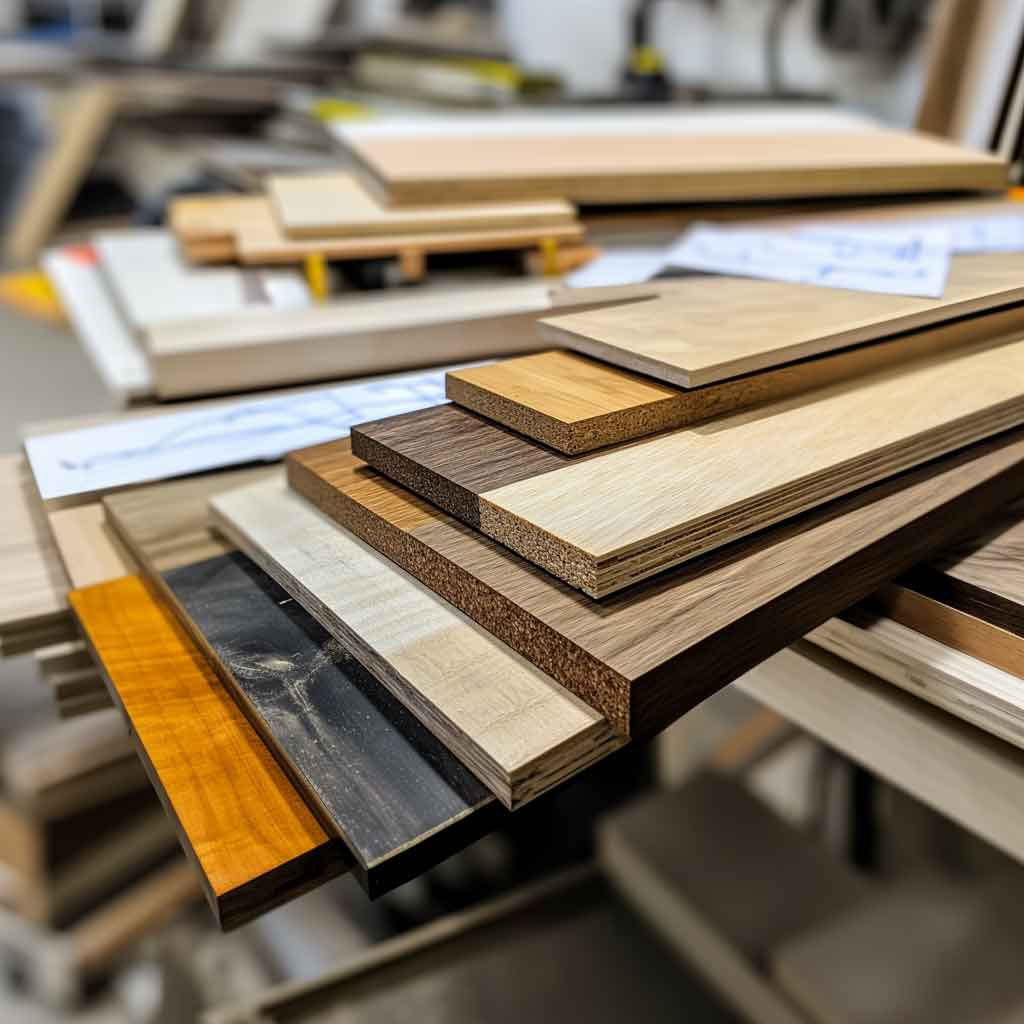

Manufactured wood encompasses several engineered products, each suited for unique industrial needs. Common types include plywood, medium-density fiberboard (MDF), laminated veneer lumber (LVL), and particleboard. These materials are produced by compressing wood fibers, veneers, or chips with adhesives under heat and pressure, resulting in uniform boards and panels that meet stringent industrial standards for strength and durability.

- Plywood: Known for strength and stability, plywood is ideal for flooring, roofing, and furniture components.

- MDF: With a smooth surface that is perfect for painting, MDF is frequently used in cabinetry and decorative panels.

- LVL: Built from layers of wood veneers, LVL offers superior strength, making it ideal for structural beams and framing.

- Particleboard: A lightweight and affordable option, particleboard works well for furniture and shelving where aesthetics are less critical.

These products allow wood manufacturers to produce consistent, scalable materials that align with industry standards for strength, size, and finish.

Benefits of Manufactured Wood in Large-Scale Production

Manufactured wood offers numerous advantages that make it essential for industries focused on high-volume production:

- Consistency and Precision

Manufactured wood provides uniform quality across large batches, reducing variations in size and shape. This consistency streamlines installation and reduces material waste, cutting labor costs for manufacturers.

- Lightweight Yet Durable

Manufactured wood combines strength with a lighter structure, ideal for wood furniture parts, interior panels, and modular construction. Its strength-to-weight ratio ensures durability without compromising ease of handling.

- Scalability

Engineered wood is readily available and well-suited for bulk orders, efficiently meeting tight deadlines. Many wood manufacturing companies depend on its scalability to complete large projects efficiently.

- Customization and Flexibility

Custom-cut wood services often use manufactured wood for intricate designs and tailored specifications, seamlessly integrating with modern manufacturing technologies.

- Cost-Effectiveness

Offering a more affordable option than natural wood, manufactured wood’s consistent quality minimizes waste, contributing to long-term savings for manufacturers.

These benefits make manufactured wood products indispensable for industries requiring high-performance, cost-effective solutions at scale.

What is Natural Wood?

Natural wood comes directly from trees, retaining its organic, unaltered composition. Known for its distinct beauty, strength, and durability, natural wood is a sought-after material in industries prioritizing quality and aesthetic appeal. Each piece of natural wood is unique, showcasing individual grain patterns, textures, and colors making it ideal for high-end furniture, architecture, and interior design applications. As a renewable resource, natural wood, when sourced responsibly, also supports sustainability goals in manufacturing.

Types of Natural Wood and Their Unique Qualities

Natural wood falls primarily into two categories: hardwoods and softwoods. Both types offer specific qualities suited for various industrial applications.

- Hardwoods: Derived from broad-leaved trees like oak, maple, and walnut, hardwoods are typically dense and strong, making them ideal for furniture and flooring. Known for their durability, hardwoods are valued for projects requiring a long-lasting, wear-resistant material.

- Softwoods: Sourced from coniferous trees like pine, cedar, and spruce, softwoods are generally lighter and easier to work with. Their versatility makes them suitable for applications such as framing, cabinetry, and decorative elements, where flexibility and lighter weight are advantageous.

Each type of natural wood provides unique benefits, allowing industries to select the most appropriate option based on strength, appearance, and intended use.

Advantages of Using Natural Wood in Large-Scale Projects

Natural wood offers several key benefits, making it a preferred choice for industries aiming for high-quality, durable, and visually appealing products.

- Aesthetic Appeal: Natural wood stands out for its organic beauty, with unique grain patterns, color variations, and textures that add warmth and character to any project. This makes it ideal for high-end furniture, decorative elements, and architectural features.

- Durability and Strength: Hardwoods, in particular, are exceptionally durable and can withstand heavy use, making them suitable for long-lasting structural applications. This durability contributes to a product’s lifespan, offering value in industries focused on quality.

- Sustainability: Responsibly sourced natural wood is a renewable resource that supports eco-friendly production. Forest management programs and certification standards ensure sustainable harvesting, allowing industries to reduce their environmental impact.

Popular Industrial Uses of Natural Wood

Natural wood is widely used across industries for its aesthetic and functional qualities, adding value to projects that demand beauty and resilience.

- Furniture Manufacturing: High-end furniture makers rely on natural wood for its elegance and strength, crafting items that showcase unique textures and natural beauty. Custom furniture pieces made from natural wood are highly sought after in residential and commercial spaces.

- Architectural Details and Structural Components: Natural wood is ideal for beams, moldings, and flooring, adding structural integrity and aesthetic warmth to buildings. Its durability makes it suitable for load-bearing elements in architectural projects.

- Interior Design and Decorative Elements: Natural wood adds a sense of luxury and sophistication to interior spaces, whether used in paneling, cabinetry, or decorative items. Its warmth and organic feel make it a popular choice for creating welcoming environments in hotels, restaurants, and retail spaces.

Natural Wood vs. Manufactured Wood: A Side-by-Side Comparison

Both natural and manufactured woods serve distinct purposes, and the right choice depends on the specific needs of each project.

- Strength and Durability in Industrial Applications

Natural wood excels in heavy-duty applications that require superior strength, such as structural beams and custom furniture. With its consistent composition, manufactured wood provides stability and is widely used in mass production, offering solutions where natural wood might be impractical.

- Aesthetic and Design Considerations

Natural wood stands out for its visual appeal, making it ideal for wood furniture parts and high-end designs. In contrast, engineered wood offers versatility for projects requiring sleek, modern aesthetics. With custom-cut wood capabilities, manufacturers can achieve precision in both natural and manufactured materials to suit specific design needs.

- Sustainability and Environmental Impact

Sustainability depends on responsible sourcing and manufacturing practices. Natural wood sourced through forest management programs supports environmental goals, while wood product manufacturing innovations reduce waste in engineered wood production. When carefully selected, both materials offer sustainable options.

- Cost-Effectiveness for Large-Scale Orders

Natural wood tends to carry higher costs due to limited availability and labor-intensive preparation. On the other hand, manufactured wood offers cost-efficient solutions for wood product manufacturers managing bulk production, delivering significant savings without compromising quality.

Meeting Large-Scale Industry Demands with the Right Wood

Both natural and manufactured woods play crucial roles in construction, furniture manufacturing, and retail design. The suitable material depends on each sector’s specific demands.

- Wood in Construction & Architecture

Natural and manufactured woods are integral to construction projects. Natural wood adds warmth and character to beams, moldings, and flooring, while wood manufacturers rely on engineered wood for scalability and customizability in large architectural designs.

- Wood in Furniture Manufacturing

High-end furniture often uses natural wood for its timeless appeal, while manufactured wood products dominate mass-market furniture production due to their affordability and production efficiency. Custom components, such as wood furniture parts, are crafted to meet specific design requirements, balancing quality with practicality.

- Retail & Hospitality Design

Retail and hospitality spaces require materials that combine aesthetics and durability. Engineered wood offers cost-effective, customizable solutions for shelves and displays, while natural timber enhances luxury interiors, reinforcing brand identity and customer experience.

- Outdoor Applications: Durability & Weather Resistance

For outdoor applications, natural wood, such as teak or cedar, is prized for its weather resistance, which is ideal for furniture and decking. Treated manufactured wood provides a more affordable option for landscape designs, delivering durability with minimal maintenance. Keller Wood Products offers expert treatment options to enhance the longevity and resilience of both natural and manufactured woods.

Key Considerations When Choosing Between Natural and Manufactured Wood

Selecting suitable wood depends on the project’s unique requirements. Each material offers distinct advantages, so it is essential to weigh key factors before deciding.

- Project-Specific Requirements

Understanding a project’s specific needs, such as strength, visual appeal, and budget, is crucial. Natural wood is often the go-to for premium projects, while wood manufacturers turn to engineered wood for large-scale orders with tight timelines.

- Sustainability & Environmental Responsibility

Businesses aiming to reduce their ecological footprint can opt for certified natural wood or explore eco-friendly innovations in wood product manufacturing. Using sustainable materials benefits the environment and enhances a company’s reputation.

- Innovations in Wood Manufacturing

Advancements in custom-cut wood technology and hybrid materials are reshaping the industry. These innovations offer new possibilities by combining the best natural and engineered woods, providing businesses with more efficient, high-quality options.

Choosing the Right Wood for Your Industry Needs

Both natural and manufactured woods play essential roles in modern industries. Deciding between them requires balancing quality, cost, and sustainability based on the specific needs of each project.

At Keller Wood Products, we specialize in wood product manufacturing for large-scale applications. Our expertise in both natural and manufactured wood ensures that businesses receive the best products for their unique needs. Contact Keller Wood Products today to explore how we can support your next project with precision-crafted solutions.