As a leading curved plywood manufacturer, Keller Products understands the versatility and reliability of plywood in construction. This article delves into the world of plywood, exploring its strengths, comparing it to traditional materials, and outlining its varied uses in the construction industry.

Unveiling the Strength of Plywood

Lightweight yet sturdy, plywood’s strength-to-weight ratio is impressive. Its layered design enhances resilience, making it perfect for construction. But let’s dive a little deeper. The cross-graining technique in plywood construction increases its strength and effectively counters wood’s natural tendency to split. This method significantly reduces the shrinkage and expansion of the material, providing a consistently strong product that withstands pressure and weight.

Infrastructure such as bridges and high-rise buildings, which require materials to bear considerable loads, could hugely benefit from plywood’s exceptional strength. With the need for long-lasting, weather-resistant materials, residential buildings also find a reliable ally in plywood.

Beyond traditional construction, plywood demonstrates its might and versatility by fitting seamlessly into marine applications, serving as an essential material in crafting boats and docks. With water resistance and robust durability, it endures challenging marine conditions, highlighting its superiority in construction. Plywood’s exceptional strength stems from its unique layered structure, enhancing its resilience to stress and wear.

Plywood Versus Traditional Materials

Ever compared plywood to concrete or metal? Well, it holds its ground. Plywood offers superior flexibility, versatility, and ease of use, surpassing many traditional construction materials.

Plywood offers superior flexibility, versatility, and ease of use, surpassing many traditional construction materials. Here’s a deeper look:

Weight

Plywood is significantly lighter than concrete or metal, easing transportation and handling. This characteristic brings about substantial savings in labor and transportation costs. Lighter materials also facilitate quicker and safer construction processes, improving overall efficiency.

Insulation

Plywood outshines metal with superior thermal insulation, enhancing a building’s energy efficiency and reducing heating and cooling costs. The result is a more comfortable, economical, and sustainable living or working space.

Flexibility

Plywood can be easily manipulated into any shape, providing greater design flexibility than concrete or metal. This flexibility allows architects and builders to realize more innovative and intricate designs, pushing the boundaries of creativity in construction.

Versatility

From structural applications like walls and roofs to aesthetic uses like flooring and furniture, plywood’s versatility is hard to rival. This adaptability reduces the need for multiple materials, simplifying logistics and enhancing the coherence of the building’s design.

Economy

Plywood, generally more cost-effective than concrete or metal, enables budget-friendly constructions without sacrificing quality. Lower cost doesn’t mean lesser value; plywood’s benefits extend beyond just savings, contributing to higher quality and more sustainable buildings.

Sustainability

Plywood’s lower carbon footprint compared to concrete and metal promotes a greener construction approach. By choosing plywood, we not only make a cost-effective decision but also a responsible one for our planet.

Its lightness, flexibility, versatility, thermal insulation, cost-effectiveness, and sustainability, collectively redefine our expectations from construction materials, firmly establishing plywood as a reliable and smart choice in the construction industry.

Types of Plywood for Construction

Softwood, hardwood, marine-grade — the plywood universe is expansive. Each variant boasts unique attributes tailored to cater to distinct construction needs. With such diversity, certain types stand out in construction for their superior properties. Here’s a look at the top picks:

Hardwood Plywood

Made from deciduous trees, hardwood plywood exhibits exceptional strength and durability, making it ideal for applications that demand high resistance, such as flooring and heavy-duty construction work. Its aesthetically pleasing grain patterns make it popular for interior finishing work.

Softwood Plywood

Typically derived from coniferous trees, softwood plywood is renowned for its lightness and flexibility. Its resilience to impact and environmental wear makes it a prime choice for structural applications such as walls and roofs.

Marine Plywood

Built for the harshest conditions, marine plywood’s water and weather resistance make it suitable for outdoor construction projects or indoor ones exposed to moisture, such as bathrooms and kitchens.

Structural Plywood

Designed for strength, structural plywood boasts enhanced load-bearing capabilities. It is often used in applications such as shear walls and diaphragms requiring high strength and rigidity.

While plywood is favored in construction for its formidable strength and versatility, the type of plywood chosen can dramatically influence the final product’s quality and longevity. Therefore, gaining a solid understanding of the various Plywood Types is pivotal.

To aid in selecting the right plywood tailored to your unique construction needs, we invite you to explore our comprehensive Plywood Buying Guide. After securing your optimal plywood, ensure its longevity by referring to our Plywood Maintenance guide. This will equip you with invaluable tips and procedures to extend your plywood’s lifespan and maintain its prime condition.

Environmental Impact of Plywood in Construction

Sustainable building? Plywood is your answer. Manufactured from renewable sources, it carries a significantly lower carbon footprint, making it a green choice. Unlike concrete or steel, plywood production requires less energy, lowering greenhouse gas emissions.

Moreover, it’s a biodegradable material, meaning it doesn’t contribute to landfill waste at the end of its lifecycle. It’s also worth noting that responsible forestry practices are often employed in its production, promoting biodiversity and forest health.

Cost-Effectiveness of Plywood

Plywood, the balance of affordability and durability. Its cost-effective nature doesn’t compromise on quality, rendering it an ideal choice for budget-driven projects. Beyond the initial lower purchase cost, plywood’s easy workability reduces labor costs and construction time, reducing overall project expenses. Its durability ensures longevity, further saving on replacement or repair costs.

Versatility of Plywood in Interior and Exterior Construction

From home exteriors to chic interiors, plywood’s charm is omnipresent. Its adaptability spans structural applications, aesthetic elements, and even intricate furniture designs. Plywood’s natural aesthetic appeal blends seamlessly with different design styles, adding warmth and character to spaces.

On the other hand, its strength and resistance to shrinking, warping, and cracking make it suitable for structural applications, such as sheathing in walls, flooring, and roofing systems.

Plywood Durability and Maintenance

Plywood stands tall against harsh weather, pests, and time. Its low maintenance requirement further solidifies its position as a go-to construction material. The layered structure of plywood offers excellent stability, minimizing the possibility of warping or splitting under stress.

Plywood treated with special coatings can resist moisture, pests, and fire, increasing its lifespan and reducing the need for regular maintenance. Hence, while its upfront cost might be higher than some alternatives, its durability and low maintenance often make plywood a more economical choice in the long run.

Innovative Plywood Construction Techniques

Engineered beams, cross-laminated timber — innovations around plywood are ground-breaking. These techniques not only bolster strength but also augment architectural possibilities.

Engineered Beams

Comprised of thin layers of wood veneer (or ‘plies’) bonded together with structural adhesive, these beams exhibit exceptional strength and rigidity. Their resistance to warping, twisting, and shrinking makes them ideal for long spans in roofs, floors, and walls.

Cross-Laminated Timber (CLT)

This is a multi-layered plywood panel, with each layer crosswise to the next. The result is a stable, strong, lightweight material ideal for walls, floors, and roofs. CLT panels can be prefabricated, reducing on-site construction time and waste.

Glue Laminated Timber (Glulam)

Glulam is made by gluing several layers of timber together under pressure and heat. Its high load-bearing capacity makes it suitable for beams, columns, and other structural elements. Glulam can also be curved for aesthetic appeal and complex architecture.

Laminated Veneer Lumber (LVL)

LVL is a type of engineered wood where multiple layers of thin wood are bonded together with adhesive. It’s stronger, straighter, and more uniform than traditional timber, making it ideal for structural applications where strength is critical.

Plywood Formworks

In concrete construction, plywood is often used as a mold into which concrete is poured. Plywood’s smooth surface, strength, and ability to hold fasteners make it perfect for this use.

These innovative construction techniques leverage and enhance plywood’s inherent strengths, creating durable, efficient, and architecturally captivating structures. They revolutionize the construction industry and pave the way for sustainable building practices.

Safety Measures for Plywood in Construction

Working with plywood? Safety first. From using protective gear to understanding load capacities, ensuring safety is paramount in handling this versatile material.

Personal Protective Equipment (PPE)

Usage of appropriate PPE, including safety glasses or goggles, gloves, and dust masks, is crucial when working with plywood to prevent injury.

Understanding Load Capacities

Plywood sheets have different strengths and load-bearing capacities. Always verify these before construction to prevent overloading and possible damage.

Proper Lifting Techniques

Employ correct lifting methods when transporting plywood sheets to avoid strain injuries.

Storage

Store plywood flat and evenly supported to prevent warping. It should be kept in dry, cool places to avoid damage from moisture or temperature extremes.

Tool Safety

Tools should be used cautiously when cutting or modifying plywood. Inspect all power tools for safety before use, follow safe operating procedures, and ensure good ventilation when applying adhesives or finishes.

Although plywood is a relatively safe material, observing these safety precautions can significantly reduce the risks associated with handling and constructing with plywood.

Top Brands for Plywood in Construction

Choosing plywood? Brands matter. Renowned manufacturers ensure premium quality, longevity, and industry compliance, promising you the best in plywood. In this competitive landscape, Keller Products holds a prominent position. Internationally recognized for reliability and quality, Keller leads in the molded plywood industry with a commitment to in-house, end-to-end services, carrying projects from concept to completion and catering to various construction needs, including custom product ranges.

Our offerings are not merely products but solutions tailored to your vision. With our custom-made molds, we can accommodate both small and large-scale projects. Whether you require lamination grade or veneered plywood, our portfolio is versatile, designed to meet diverse construction requirements. Choosing Keller Products means investing in quality, innovation, and a customer-focused experience that sets new standards in the plywood industry.

Case Studies: Successful Plywood Construction Projects

From the Metropol Parasol to The Longhouse, the world bears testimony to the mastery of plywood in construction. These case studies echo plywood’s promise of architectural brilliance. Here are some noteworthy examples:

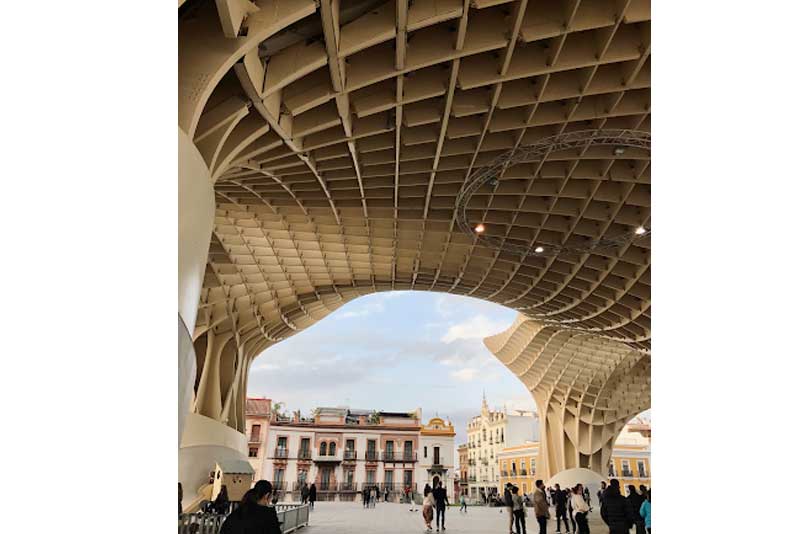

Metropol Parasol

The largest wooden structure in the world, Metropol Parasol is an architectural marvel in Seville, Spain. Constructed with birch plywood, this impressive edifice displays the resilience and flexibility of plywood, defying conventional design principles with its unique and intricate parasol-shaped structure.

The Longhouse

Nestled in the heart of nature, The Longhouse in Massachusetts, USA, showcases the versatility of plywood. Its striking design features interior and exterior walls made entirely from plywood, blending beautifully with the surrounding landscape while ensuring the building’s robustness.

The Endesa Pavilion

This energy-efficient solar structure in Barcelona, Spain, utilizes plywood in a stunning manner. With a unique geometric design, the plywood components of the pavilion are computer-milled to optimize solar gain, demonstrating the material’s versatility and sustainability.

Kielder Observatory

Located in Northumberland, UK, this astronomical observatory uses plywood. The building’s construction material was chosen for its ability to withstand the demanding weather conditions of its location. Its interior, finished in birch plywood, provides a warm contrast to its stark exterior, highlighting the versatility of plywood.

These projects emphasize the undeniable potential of plywood as a material in construction, each demonstrating a unique application of plywood’s versatility, durability, and aesthetic appeal. Their remarkable construction confirms plywood’s standing as an excellent material choice for creating architectural masterpieces.

Future of Plywood in the Construction Industry

Innovative, eco-friendly, and versatile – plywood is poised to lead the future of construction. As technological advancements elevate its potential, plywood’s journey has only begun. With the construction industry evolving to prioritize sustainability, plywood’s environmental benefits come into sharper focus. Innovations such as cross-laminated timber and engineered beams amplify plywood’s strengths, offering a robust alternative to traditional materials.

Furthermore, the synergy of plywood with digital fabrication techniques like CNC machining unlocks the potential for intricate architectural solutions, making plywood a pivotal player in future construction trends. The versatile material’s journey in the construction sector is set to revolutionize the industry, fostering economic viability and environmental responsibility.

How to Choose the Right Plywood for Your Construction Project

Selection is key. Understanding your project needs, assessing plywood types, and considering environmental factors are critical steps to finding your plywood match. Begin by defining the project requirements: Are you looking for strength, flexibility, aesthetics, or a blend of all? Each plywood type, from hardwood to marine, offers unique attributes that cater to distinct needs. Evaluate them against your project’s demands to narrow down your options. Furthermore, consider the environmental conditions of the project location.

Will the plywood be exposed to moisture, extreme temperatures, or outdoor elements? Some plywood variants like marine plywood exhibit superior resistance to these conditions. Finally, never overlook the sustainability aspect. Opt for plywood manufactured from renewable sources, thereby contributing to a greener planet. This journey of selection might seem overwhelming, but with the right guidance, you can seamlessly navigate it. Feel free to contact Keller Products, your trusted plywood partner, for expert advice and quality plywood solutions.

Conclusion: The Indispensable Role of Plywood in Construction

Plywood in construction – a game-changer indeed. Combining strength, versatility, and sustainability, plywood has carved its niche in the construction industry, proving its indispensability time and again.

The journey of plywood in construction is a testament to innovation and adaptability. As we continue to explore its untapped potential, one thing is certain — plywood’s role in shaping the future of construction is colossal, vital, and irreplaceable.

As your dedicated partner, Keller Products extends its industry expertise and unparalleled services to help you harness the full potential of plywood. With our exceptional quality products and custom solutions, we’re ready to empower your construction project, ensuring it stands the test of time and delivers remarkable value. Don’t hesitate to reach out!

Related Article: Different Types of Plywood

FAQs

Here, we will address the benefits, comparisons with traditional materials, types, sustainability aspects, and exemplary projects related to plywood.

What are the benefits of using plywood in construction?

Plywood offers numerous benefits, such as strength, versatility, and cost-effectiveness. Its layered composition provides inherent durability, enabling it to resist cracking, warping, and twisting, making it a superior choice for various construction applications.

How does plywood compare to traditional construction materials?

Compared to traditional materials such as solid wood or steel, plywood exhibits remarkable resistance to deformation. Its engineered design allows for precise cuts without the risk of splitting, a common problem with solid wood. This makes plywood a reliable and flexible choice for construction.

What are the different types of plywood used in construction?

Various types of plywood are utilized in construction, each serving different purposes. Softwood Plywood, typically made from pine, spruce, or fir, is widely used for structural applications due to its strength and durability. On the other hand, Hardwood Plywood, crafted from species like birch or oak, is preferred for interior purposes owing to its aesthetic appeal and superior finish.

How does plywood contribute to sustainability in construction?

Plywood is inherently sustainable as its production process is more efficient compared to solid wood, utilizing almost all parts of a tree. This helps minimize waste, thus contributing to environmental conservation. Moreover, it can be certified as sustainable by organizations like the Forest Stewardship Council (FSC), assuring that it comes from responsibly managed forests.

What are some noteworthy projects utilizing plywood in construction?

Plywood has been used to construct remarkable architectural marvels, demonstrating its adaptability and versatility. Metropol Parasol, located in Seville, Spain, is an iconic project mainly constructed from plywood. The Longhouse in Norfolk, England, is another example, showcasing the potential of plywood as a primary building material. These projects exemplify plywood’s unique properties and ability to shape our built environment.